Equipment

At Meca Tech Systems, the experts of semiconductors, displays(FPD), electricity and electronics with

specialties in the camera module test sockets are developing equipment that maximizes synergy

effects over test procedures and production procedures prior to the module production.

specialties in the camera module test sockets are developing equipment that maximizes synergy

effects over test procedures and production procedures prior to the module production.

FPCB Bonder

-

FeatureㆍApplicable to the FOG & COG of small and medium LCD Module and the Camera Module FPCB Bonding

ㆍManual & Auto Align available by Camera Module Monitoring & Vision Inspection

ㆍSecuring accuracy and reliability of temperatures and pressures

ㆍCompatibility of loading Jigs and compensation of the evenness of the tip available

ㆍHigh productivity and reliability

ㆍpriceSpecifications

Application Device LCD FOG & COG, Camera Module FPC Lo/Unloading Method Manual & Auto Available(Magazine Type) Feeder Method(Seal Tape) Reel to Reel / Step Motor drive & Manual drive Index Time 2sec/1ea UPH Optimization by customer request Control Unit PLC & PC Base (Touch Panel) Air Requirements 5kgf/㎠ (Clean Dry Air) Electric Requirements 220 VAC , Single Phase , 50Hz ~ 60Hz Dimension 900(W) x 900(D) x 1600(H)

Lens Protection Tape Attach

-

FeatureㆍCoping with the low and the high density pixel camera module align is available.

ㆍTape attachment without tray shifts is available (process reduction)

ㆍSetting the moving distance between protected tape pitch and the tray pitch is

available.

ㆍModule conversion available

ㆍHigh productivity and reliability

ㆍReasonable priceSpecifications

Application Device Mobile Camera Module Lo/Unloading Method Manual & Auto Available(Soft Tray) Align Method Vibration Align or Magnetic Align (Tolerance ±1mm) Index Time 3sec/5ea UPH Optimization by customer request Control Unit PLC & PC Base (Touch Panel) Air Requirements 5kgf/㎠ (Clean Dry Air) Electric Requirements 220 VAC , Single Phase , 50Hz ~ 60Hz Dimension 900(W) x 900(D) x 1600(H)

Auto LED Test Handler

-

FeatureㆍHigh productivity thanks to the index turret method implemented

ㆍAngle division and accurate locating by DD Motor

ㆍEngineering analysis available by establishing database

ㆍMarking inspection by vision

ㆍPackaging the reel tape of quality materials

ㆍHigh productivity and reliability

ㆍReasonable priceSpecifications

Application Device Mobile Camera Module Lo/Unloading Method Bulk & Tube Type Unloading Method 256 Bins Sorting & Reel Tape Index Time Optimization by customer request UPH Optimization by customer request Control Unit PLC & PC Base (Touch Panel) Air Requirements 5kgf/㎠ (Clean Dry Air) Electric Requirements 220 VAC , Single Phase , 50Hz ~ 60Hz Dimension 1250(W) x 900(D) x 1650(H)

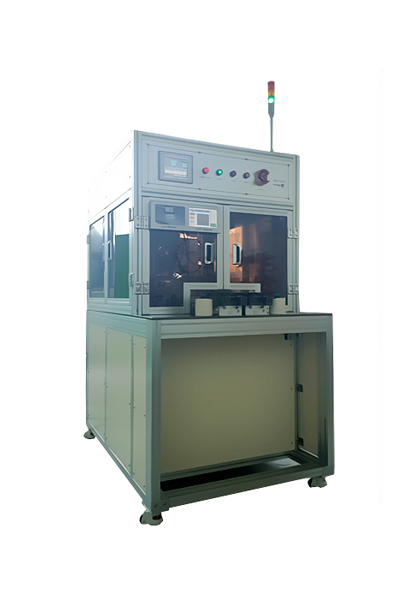

Auto Soldering System

-

FeatureㆍCoping with the low and the high density pixel camera module align is available.

ㆍTape attachment without tray shifts is available (process reduction)

ㆍSetting the moving distance between protected tape pitch and the tray pitch is

available.

ㆍModule conversion available

ㆍHigh productivity and reliability

ㆍReasonable priceSpecifications

Application Device All Strip & Unit Device Lo/Unloading Method 5sec/1ea Index Time 2sec/1ea UPH Optimization by customer request Control Unit Embedded System (UI : Touch Panel & Teaching Pendent , JOG) X, ,Y,Z ,R - Axis 4 Axis Robot & Encoder apply Resolution (Robot / Wire) ±10㎛ / 0.1mm Air Requirements 5kgf/㎠ (Clean Dry Air) Electric Requirements 220 VAC , Single Phase , 50Hz ~ 60Hz Dimension 1000(W) x 1200(D) x 1600(H)